How to confirm gate riser system of impeller investment castings?

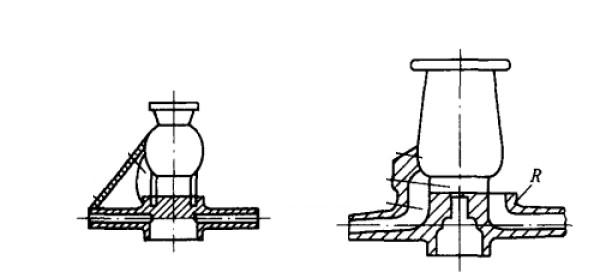

Impeller investment casting parts are typical investment castings.Common material of such parts are stainless steel.There are high quality requirements for casting quality,machining,dimension accuracy and surface roughness.Detailed structure like picture 2-24.Below are some aspects that the effect of impeller investment castings structure on casting quality:

Picture 2-24

1.As the outline of impeller investment castings is thick,if we do not lead to hot section and feeding is insufficient,then it will cause shrinkage cavity after machining hole sections.

2.The wall thickness of section R in impller covers is large and hot section is exsited.We normally set a seal groove in this part.If ignore the feeding of R section,then it will be easy to occur shrinkage cavity when machining slot of impeller investment castings.

3.As the inlet and outlet of impeller blade is thin and inlet impeller blade is mostly arc.If pouring position is not correct,then it may cause own watering.

4.For large plane impeller investment castings,it is easy to produce defects like inclusions.

According to above characteristics,we could adopt following solutions:When we do not cast out shaft holes,the impeller inlet side can be plane down, a spherical head is set on the shaft hole.In the sealing end, placing three side risers with certain width 120° distribution.For impeller diameter bigger than 2000 mm,because of increased surface area and the effect of injection rate,setting up the air flow should be considered.When the shaft hole is cast out, the impeller can be imported flat end up pouring.