Technical guidance for designing investment castings

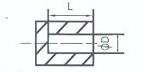

1.Liner tolerance(mm) 2.Limit dimension for cast holes and slots

| Dimensions | Normal | Premium |

| 0-10 | ±0.12 | ±0.1 |

| 10-15 | ±0.20 | ±0.13 |

| 15-20 | ±0.25 | ±0.15 |

| 20-30 | ±0.30 | ±0.20 |

| 30-50 | ±0.4 | ±0.25 |

| 50-75 | ±0.5 | ±0.35 |

| 75-100 | ±0.65 | ±0.45 |

| 100-125 | ±0.8 | ±0.6 |

| 125-150 | ±1 | ±0.7 |

| 150-175 | ±1.2 | ±0.8 |

| 175-200 | ±1.5 | ±0.9 |

| 200-250 | ±1.8 | ±1.1 |

| >250 | ±0.8% | ±0.5% |

| Items | Hole dia.(mm) | L/D |

|

Ø2-Ø3 | L/D≤2 |

| Ø4-Ø7 | L/D≤5 | |

| ≥Ø8 | L/D≤10 | |

|

Ø2-Ø3 | L/D≤1 |

| Ø4-Ø7 | L/D≤2.5 | |

| ≥Ø8 | L/D≤3.5 | |

| Deeper and more complicated holes and slots can be casted by using soluble wax cores and ceramic cores. | ||

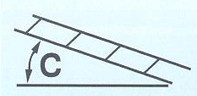

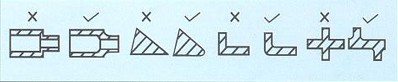

3.Angle tolerance

| Angle type |  |

|

|

| Normal | ±1° | ±2° | ±2° |

| Premium | ±0.5° | ±1° | ±1° |

| Avoid quick changes of casting structure,use fillet radius on internal angle when possible,which is no less than R0.3. |  |

||

4.Tolerance for flatness,straightness,roundness 5.Wide and weight range

| Dimensions | Normal | Premium |

| 0-25 | 0.2 | 0.1 |

| 25-50 | 0.4 | 0.2 |

| 50-100 | 0.6 | 0.3 |

| 100-150 | 0.8 | 0.4 |

| Item | Size | Premium |

| Outline dimension(mm) | 100*620*380 | <100 |

| Weight(kg) | 0.001-100 | 0.1-1.5 |

| Min. wall thickness(mm) | 0.5 | 5-10 |

6.Surface roughness(Ra/um)

| Rough castings |

Weight>5kg Main wall thickness>12mm |

3.2-6.3 | The surface finish of investment castings we could provide with are as the following:zinc plating,chrome plating and nickel plating for carbon steel investment castings and low alloy steel castings;Hand dull polishing,mirror polishing,electrolytic polishing and passivation treatment for stainless steel investment castings and sand blasting for all the investment castings. |

|

Weight<5kg Main wall thickness<12mm |

1.6-3.2 | ||

| Finished castings | 0.8-1.6 |